Long

Aluminium solaris panel frame ad duplex speculum solaris panel

Solaris frame Model: XXX * XXX

Crassitudo: 30mm Altitudo

Typus: Aluminium FORMA installed

Rudis Material: (VI) V Aluminium Alloy

Section Size: XXX * 30mm

Slote Size: 6mm

MOQ: 500Sets

Color argentum

Payment Terms: TT et L / C

Communia Specifications: MMCDLXV * 1134mm

Secretum

Aluminium solaris panel frame ad duplex speculum solaris panel

Solaris frame Model: XXX * XV

Crassitudo: 30mm Altitudo

Typus: Aluminium FORMA installed

Rudis Material: (VI) V Aluminium Alloy

Section Size: XXX * 15mm

Slote Size: 6mm

MOQ: 500Sets

Color argentum

Payment Terms: TT et L / C

Communia Specifications: MMCDLXV * 1134M

Bracket

Aluminium solaris panel frame ad duplex speculum solaris panel

Solaris frame Model: 45.2 * 45.2 * 7.5

Crassitudo: 45.2mm Altitudo

Typus: Aluminium FORMA installed

Rudis Material: (VI) V Aluminium Alloy

Artus Size: 45.2 * 45.2 * 7.5mm

MOQ: 500Sets

Color argentum

Payment Terms: TT et L / C

Communia Specifications: MMCDLXV * 1134mm

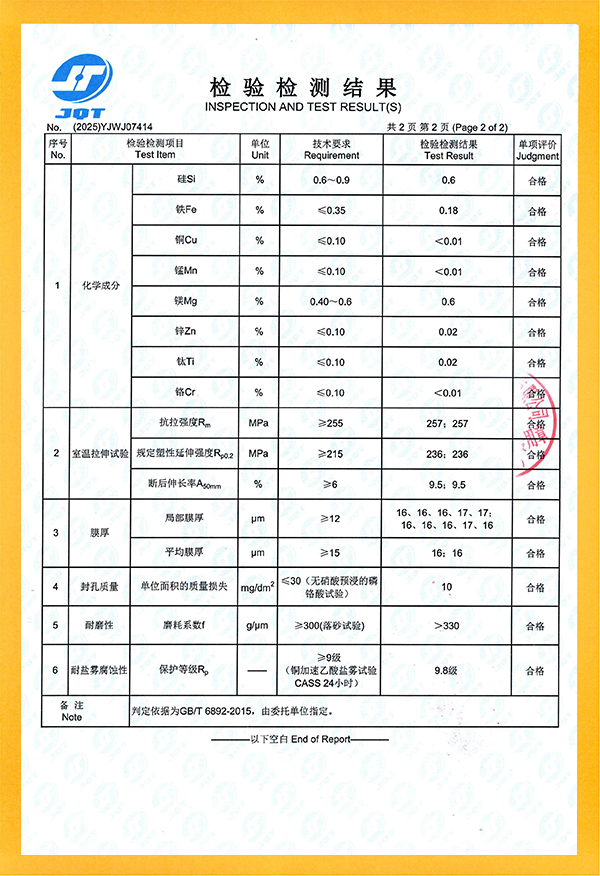

Chemical compositionem Aluminium Alloy:

Mixtura |

Si |

Fes |

Cu |

Mn |

Mg |

Credo |

ZN |

Ti |

Alii |

Al (min) |

6063 |

0.2-0.6 |

0.35 |

0.1 |

0.1 |

0.45-0.9 |

0.1 |

0.1 |

0.1 |

0.15 |

requiesco |

6005 |

0.6-0.9 |

0.35 |

0.1 |

0.1 |

0.4-0.6 |

0.1 |

0.1 |

0.1 |

0.15 |

requiesco |

Mechanica proprietatibus Aluminium Alloy:

Mixtura |

Ingenium |

Crassities |

T / B (MPA) |

O / σ 0.2 (MPa) |

ELEG./ δ % |

Duritia / HW |

6063 |

T5 |

Tago 0.8 |

Tago160 |

Tago110 |

Tago8 |

Tago8 |

6063 |

T6 |

Tago 0.8 |

Tago205 |

Tago180 |

Tago8 |

Tago10 |

6005 |

T5 |

Tago 0.8 |

Tago260 |

Tago240 |

Tago6 |

Tago12 |

6005 |

T6 |

Tago 0.8 |

Tago270 |

Tago250 |

Tago6 |

Tago14 |

Omnes solaris panel magnitudinum ut infra pro referat:

Power (W) |

Numerus cellulis (PCs) |

Magnitudinem cellulis (mm) |

Solaris Panel frame Size (mm) |

Pondus (kg) |

5 |

II * XVIII |

LXXVIII * XII |

280x190x17 |

0.7 |

10 |

IV * IX |

LII * 31.2 |

250x350x17 |

1.2 |

20 |

IV * IX |

LXXVIII * XXXIX |

420x360x17 |

2.3 |

30 |

II * XVIII |

CLVI * XXVI |

360x550x20 |

2.5 |

40 |

IV * IX |

CLVI * XXXIX |

670X 420x25 |

3.2 |

50-60 |

IV * IX |

CLVI * LII |

540x670x25 |

4.2 |

80-90 |

IV * IX |

CLVI * LXXVIII |

780x670x30 |

6.6 |

100 |

IV * IX |

CLVI * CIV |

1000x670x30 |

8 |

110-120 |

IV *18 |

CLVI * LII |

1020x670x35 |

8.8 |

130 |

IV * IX |

CLVI * CXVII |

1120x670x35 |

10.5 |

140 |

IV * IX |

CLVI * LXIII |

1200x670x35 |

10.5 |

150-180 |

IV * IX |

156,75 156,75 |

1480x670x35 |

12 |

190-200 |

VI * XII |

CXXV * CXXV |

1580x808x35 |

15.5 |

210-230 |

VI *8 |

156,75 156,75 |

1320x992x35 |

17 |

250-270 |

VI *9 |

156,75 156,75 |

1482x992x40 |

18 |

280-310 |

VI *10 |

156,75 156,75 |

1640x992x40 |

18 |

340-380 |

VI *12 |

156,75 156,75 |

1956x992x40 |

23 |

460-500 |

8*12 |

156,75 156,75 |

1956x1310X45 |

29 |

Factory introductio:

Jiangyin Zhonghao Energy Technology Co., LTD erat statutum in MMXX, .Our Company praesertim proelium in investigationis et progressionem, vestibulum, et applicationem ex solaris frame products, automated materiae. Et principalis products includit photovoltaic frame products, aedificium, integrated photovoltaic (Bipv) products, et photovoltaic subsidium. Zhonghao Energy Technology Co., LTD products notum est in luce, princeps stabilitatem, optimum tempestas resistentia, et fortis resistentia, et late in photovoltaic agro.

Zhonghao industria technology committitur occurrens progressionem necessitates in Solaris Energy Market in Sina, active researching novus products et continuously improving novum technologies. . In comitatu habet statutum diu terminus et stabilis cooperantem relationes cum pluribus ducens component artifices, continuously enhancing eius core competitivitas et foro participes. Eius products et Transierunt plures Internationalis certificaciones, comprehendo ISO (IX) I: MMXV Quality Management System et ISO (XIV) CMXV Aliquam System Certifications. Products sunt popularibus et domestice et internationally, cum LXX% praesertim vendidit ad altus-finem fora in Medio Oriente, Japan, Meridionalis Korea, Singapore, India, Vietnam et Thailand.

Corporate Visio: Be magna Enterprise

Corporate Missionis: develop solis industria pro beneficium omnium hominum -

Enterprise Spiritu: Sinceritas, Simplicitas, Reverentia, gratiam

Enterprise opinionem: sit amet homo et operatur religiose

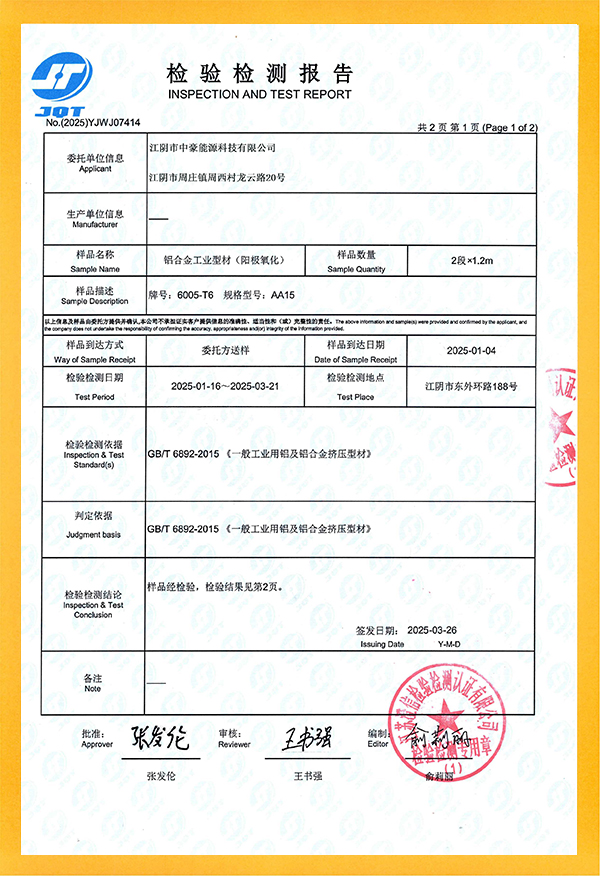

Factory certificatorium:

Productio processus:

Et solaris panel frame est key supporting structuram de photovoltaic moduli. Est maxime factum est de Aluminium Alloy materiae et habet characteres luminis pondus, corrosio resistentia et princeps vires. Productio processus potest dividitur in sequentibus core links:

I. Material Preparatio et Profile Extrusion

Aluminium Alloy Electio: Communiter (VI) LXIII-T5 seu (VI) LXI-T6 Aluminium Alloys oportet obviam de necessitatibus tensile fortitudinem (≥160mpa) et elongatio (≥8%).

Extrusionem CUMATIUM: Aluminium virga calescit ad 450-500 ℃ per fingunt et extruditur in a profile cum specifica crucem-sectional figura, sequitur aere-refrigerationem extinguendo ad augendam duritiam.

II. Calor curatio et senescit confirmans

Senescentis curatio: et extruditur profile necessitates ad custodiri in anus fornacem ad circiter CC ℃ ad 4-6 horis ad permitti mechanica proprietatibus (ut durum augmentum magis quam XXX%).

III. Superficiem curatio (Anodization )

SHYSBLASTING PRETARATIO: Sandblasting adhibetur ad removendum superficiem impudicitiis et incremento asperitas ad augendae adhaesionem in Oxide layer.

Anodizing: electricity est applicari in sulphuric acidum electrolytici ad generare 15-25μm densissima cadmiae film ut amplio corrosio resistentia (sal imbre test potest pervenire plus quam M horis). Nigrum vel color oxidatio potest delectus obviam aesthetic requisita.

IV. Precision machining

Cutting: Usus a XLV ° Bavel duplex caput vidit ut interficiam in profile ad requiritur longitudo de component, cum accurate imperium in ± 0.5mm.

Punching et slotting: plene automatic punching machina processibus adscendens foramina et foramina (ut in socors consilio de quibus in patentibus pro anti-pulveris cumulation structure).

V. Conventus et qualis imperium

Anguli fixing: quattuor angulos frame connexa per immaculatam ferro angulos et triplici inspectionem adhibetur ut verticality et airtightness.

Inspectionem Signa: comprehendo dimensional tolerantia (ut ± 0.2mm), cadmiae film crassitie deprehensio (spectrophotometer) et el test (reprehendo pro Cracks).

VI. Packaging et anti-damnum design

Film tutela: PE tutela amet applicantur ad superficiem ne scalpit in translationem.

Interlayer curvis: Quisque frame separata a chartam interlayer ne friction damnum. Anti-pulveris cumulus Design, exempli gratia, in 'Guide Superficies + card Slote ' structuram in Tongwei solaris est patentibus Achieves sui Purgato per optimizing et figura, reducing operationem et sustentacionem costs.

English

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

සිංහල

Oʻzbekcha

অসমীয়া

Български

Esperanto

guarani

Kurdî

Cymraeg

isiZulu