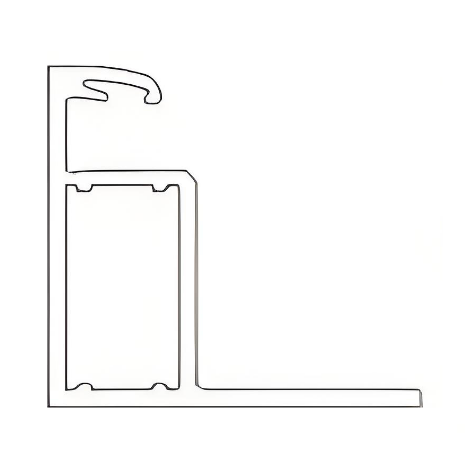

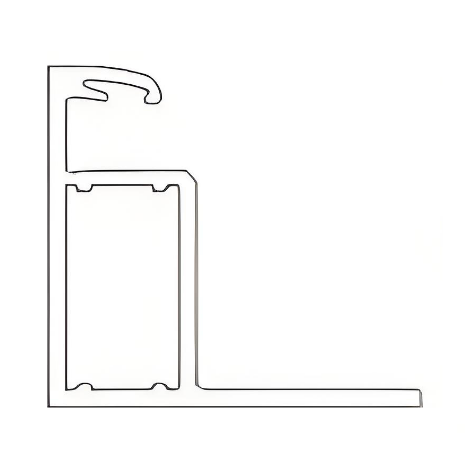

Long Side

Aluminum solar panel frame for double glass solar panel

● Solar frame model: Custom

● Thickness: 33mm height

● Type: Aluminium frame installed

● Raw material: 6005 aluminum alloy

● Frame section size: CustomSlot size: 6.2mm

● MOQ: 500sets

● Color: silver

● Payment terms: TT or L/C

● Common specifications: Custom

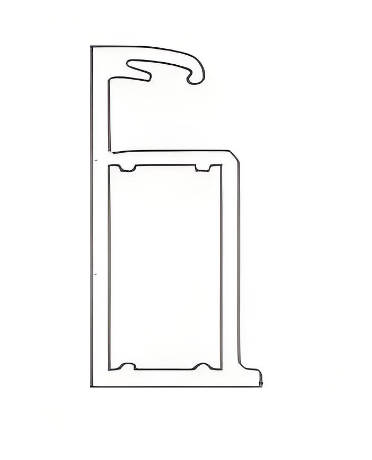

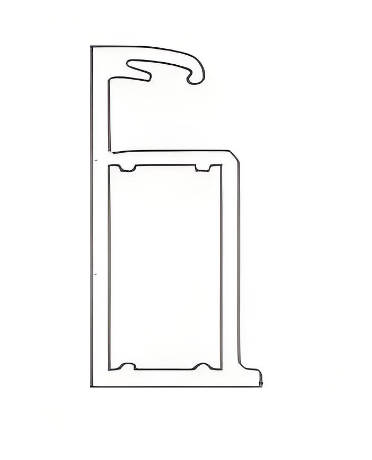

Short side

Aluminum solar panel frame for double glass solar panel

● Solar frame model: Custom

● Thickness: 33mm height

● Type: Aluminium frame installed

● Raw material: 6005 aluminum alloy

● Frame section size: Custom

● Slot size:6.2mm

● MOQ: 500sets

● Color: silver

● Payment terms: TT or L/C

● Common specifications: Custom

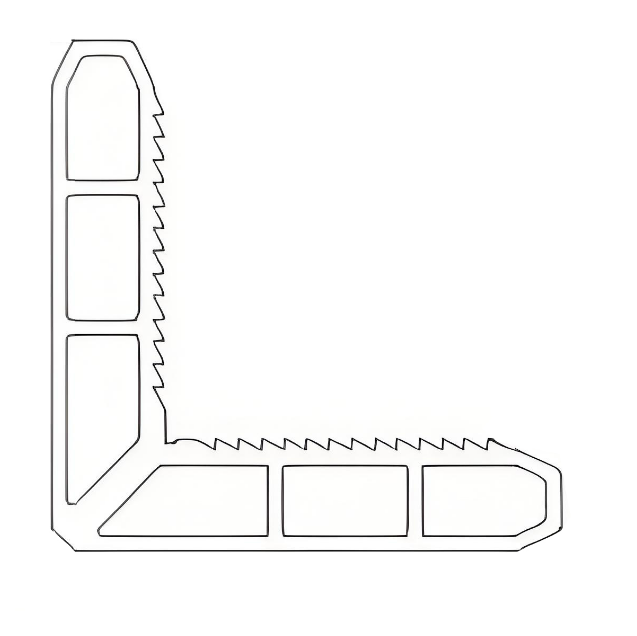

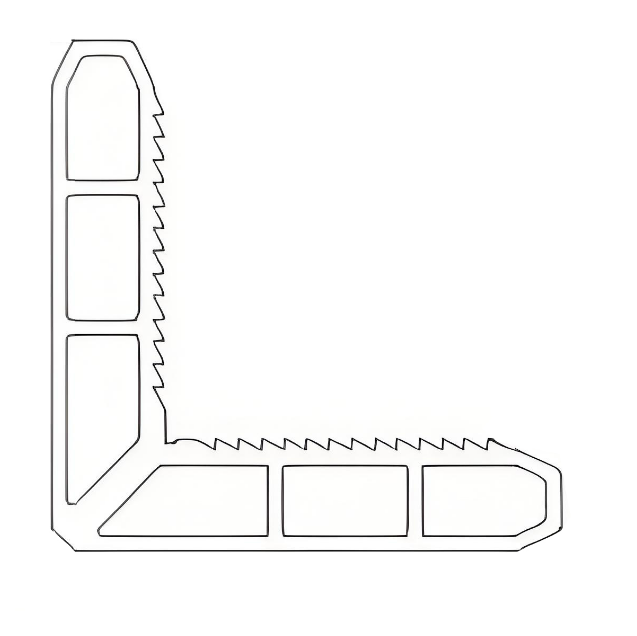

Bracket

Aluminum solar panel frame for double glass solar panel

● Solar frame model: Custom

● Thickness: 40mm height

● Type: Aluminium frame installed

● Raw material: 6005 aluminum alloy

● Frame section size: Custom

● MOQ: 500sets

● Color: silver

● Payment terms: TT or L/C

● Common specifications: Custom

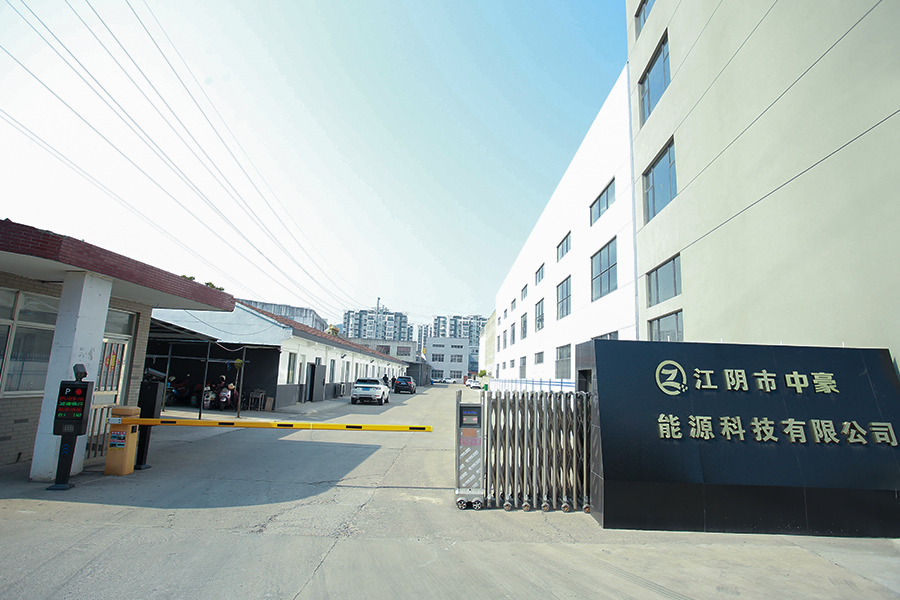

Factory Introduction:

Jiangyin Zhonghao energy Technology Co., LTD was established in 2020, .Our company primarily engages in the research and development, manufacturing, and application of solar frame products, automated frame production lines, and green energy structural materials. Its main products include photovoltaic frame products, building-integrated photovoltaic (BIPV) products, and photovoltaic support structures. Zhonghao Energy Technology Co., LTD products are known for their lightweight, high stability, excellent weather resistance, and strong corrosion resistance, and are widely used in the photovoltaic field.

Zhonghao Energy Technology is committed to meeting the development needs of the solar energy market in China, actively researching new products and continuously improving new technologies. . The company has established long-term and stable cooperative relationships with several leading component manufacturers, continuously enhancing its core competitiveness and market share. Its products have passed multiple international certifications, including ISO 9001:2015 Quality Management System and ISO 14001:2015 Environmental Management System certifications. The products are popular both domestically and internationally, with 70% primarily sold to high-end markets in the Middle East, Japan, South Korea, Singapore, India, Vietnam, and Thailand.

Corporate Visio: Be a great enterprise

Corporate Mission:Develop solar energy for the benefit of all mankind -

Enterprise Spirit: Sincerity, Simplicity, Reverence, Gratitude

Enterprise Belief: Be an upright person and work conscientiously

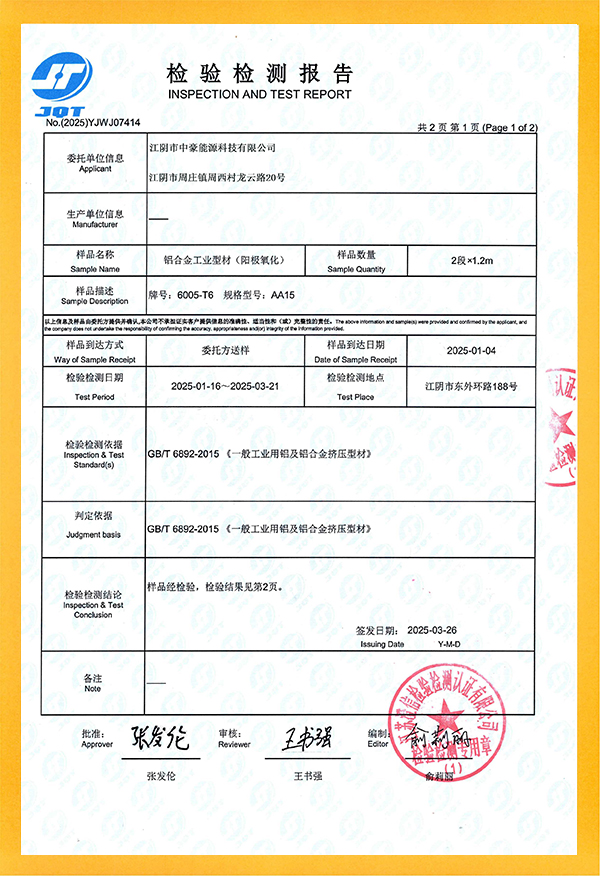

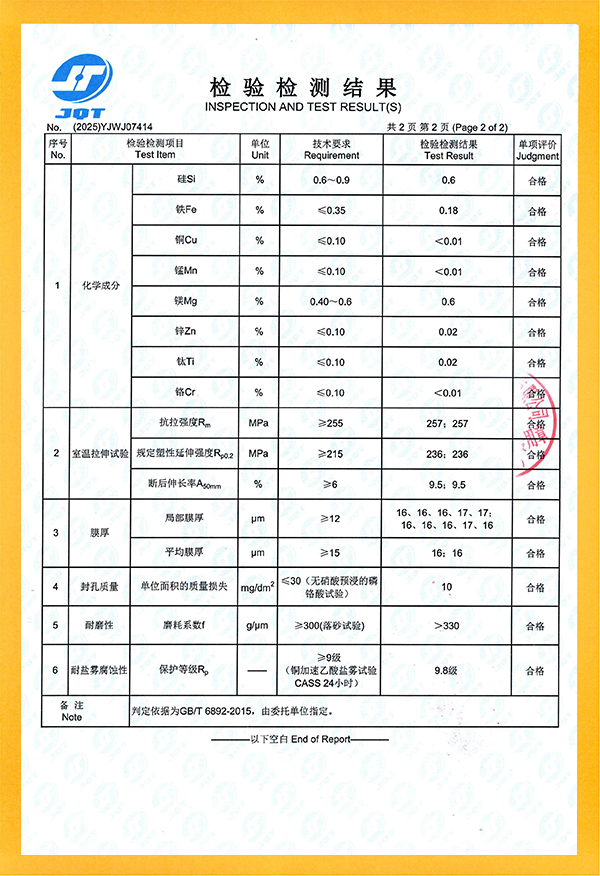

Factory Certificate:

Production process:

The solar panel frame is the key supporting structure of the photovoltaic module. It is mainly made of aluminum alloy materials and has the characteristics of light weight, corrosion resistance and high strength. The production process can be divided into the following core links:

1. Raw material preparation and profile extrusion

Aluminum alloy selection : Commonly used 6063-T5 or 6061-T6 aluminum alloys must meet the requirements of tensile strength (≥160MPa) and elongation (≥8%).

Extrusion molding : The aluminum rod is heated to 450-500℃ through a mold and then extruded into a profile with a specific cross-sectional shape, followed by air-cooling quenching to increase hardness.

2. Heat treatment and aging strengthening

Aging treatment : The extruded profile needs to be kept in an aging furnace at about 200℃ for 4-6 hours to allow the alloy elements to precipitate evenly and significantly improve the mechanical properties (such as hardness increase by more than 30%).

3. Surface treatment (anodization)

Sandblasting pretreatment : Sandblasting is used to remove surface impurities and increase roughness to enhance the adhesion of the oxide layer.

Anodizing: Electricity is applied in sulfuric acid electrolyte to generate a 15-25μm thick oxide film to improve corrosion resistance (salt spray test can reach more than 1000 hours). Black or other color oxidation can be selected to meet aesthetic requirements.

4. Precision machining

Cutting: Use a 45° bevel double-head saw to cut the profile to the required length of the component, with an accuracy control within ±0.5mm.

Punching and slotting: Fully automatic punching machine processes mounting holes and slots (such as the slot design mentioned in the patent for anti-dust accumulation structure).

5. Assembly and quality control

Corner fixing: The four corners of the frame are connected by stainless steel corners, and triple inspection is used to ensure verticality and airtightness.

Inspection standards: Including dimensional tolerance (such as ±0.2mm), oxide film thickness detection (spectrophotometer), and EL test (check for hidden cracks).

6. Packaging and anti-damage design

Film protection: PE protective film is applied to the surface to prevent scratches during transportation.

Interlayer winding: Each frame is separated by a paper interlayer to avoid friction damage. Anti-dust accumulation design: For example, the "guide surface + card slot" structure in Tongwei Solar's patent achieves self-cleaning by optimizing the frame shape, reducing operation and maintenance costs.

English

繁體中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

فارسی

Slovenčina

Slovenščina

Svenska

українська

Ελληνικά

Suomi

עברית

Latine

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

සිංහල

Oʻzbekcha

অসমীয়া

Български

Esperanto

guarani

Kurdî

Cymraeg

isiZulu